MACHINING

Depending on the size and geometry of your project, we will ensure precision and efficiency. Our extensive industry knowledge allows us to streamline our operations, resulting in shorter lead times for your projects. Whether the job is large or small, don't hesitate to contact us for a quote on your next project.

-- TURNING -- MILLING -- GRINDING -- PORTABLE DRILLING & TAPPING CNC Turning: Haas ST-10 Lathe Equipped With: • 6000 RPM / 15HP Spindle • 6.5" Hydraulic Chuck or Royal QG-45 Collets for Work Holding • 12 Tool Turret • Bar Feeder (Ø1.75 x 48" Capacity) • Tail Stock • Chip Conveyor • Parts Catcher • Machine Travels (X - 7.88" / Z - 16") • Max Cutting Dia. 12" / Max Cutting Length 16" - Depending on work holding) Manual Turning: Equipment: Bridgeport / Romi EZ Path I Parts: Up to Ø8" x 40" Operations: Turning, Facing, Boring, Knurling, Threading & Grooving CNC Milling: DN Solutions (Doosan) SVM-4100 Vertical Machining Center Equipped With: • 12,000 RPM Spindle • 40 Taper Dual Contact Taper • 30 Tool Dual Arm ATC • Spindle Chiller • Thru Spindle Coolant • Renishaw Probing Machine Travels (X-30", Y-16", Z-20") Surface Grinding: Mitsui MSG-200MH 6"x12" Chuck Portable Equipment: Mag Base Drill - Unibore CMD400 Capacity - Ø1-1/2" Electric Tapping Arm - 120V AC Capacity - M30 or 1-1/8" UNC

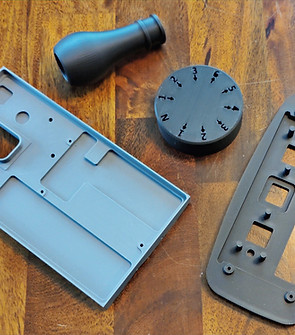

3D LASER SCANNING & PRINTING / PROTOTYPING

When we design and build for customers we are able to provide 3D scanning services via Revopoint MetroX laser scanning technology. Scans can then be converted into solid models for 3D printing, machining or other fabrication needs. 3D printing services are available for many plastic materials, including resins blended with carbon fiber. Revopoint MetroX Laser Scanner Blue Laser Line & Full-field Structured Light 3D Scanner: ꔷ 4 Flexible Scanning Modes ꔷ Metrology-grade Accuracy: Up to 0.02 mm ꔷ Volumetric Accuracy: 0.025 mm + 0.05 mm × L (m) ꔷ Up to 7,000,000 Points/s in Full-field Structured Light Mode ꔷ Up to 800,000 Points/s in Multi-line Laser Mode Bambu Labs X1C 3D Printer: ꔷ Multi Color & Multi Material Capability ꔷ High quality printing with 7 μm Lidar Resolution ꔷ High speed CoreXY with 20000 mm/s² Acceleration ꔷ Dual Auto Bed Leveling

CAD/CAM DESIGN SERVICES

- REVERSE ENGINEERING -

At Iron Country Machine, we leverage CAD/CAM technology to bring your project to life with precision and expertise. Whether it's reverse engineering for repairs or prototype designing, we offer solid modeling & machine programming services to meet your needs. Our diverse experience allows us to tackle a wide range of projects. We are committed to transforming your vision into reality through open communication and delivering products that meet your expectations. Let's collaborate to make your ideas a reality! Solid Modeling & CNC Programming via Autodesk Fusion 360 Importing/Exporting of all major file formats including: Step, Igs, Dwg, Dxf, Stl, Parasolids, etc. Project Examples: Custom tools, Industrial equipment & Fixtures

EQUIPMENT AT IRON COUNTRY MACHINE

CNC TURNING

Haas ST-10 2 Axis Lathe

(Equipped with 6-1/2" Chuck, Tailstock & Bar feeder)

Haas Bar Feeder

(Feeds up to Ø1-3/4" × 4' Bar Stock)

Bridgeport EZ Path I CNC Lathe

(Size 16" × 40")

SURFACE GRINDING

Mitsui MSG-200MH

(Chuck: 6" × 12")

CNC MILLING

Doosan SVM-4100 3 Axis VMC

(Travels: X 30", Y 16", Z 20")

3D SCANNING & PRINTING

Revopoint MetroX Laser Scanner

Bambu Labs Printer

X1C with AMS

LET'S START YOUR NEXT PROJECT

11144 Dupont Road

Hibbing, MN 55746